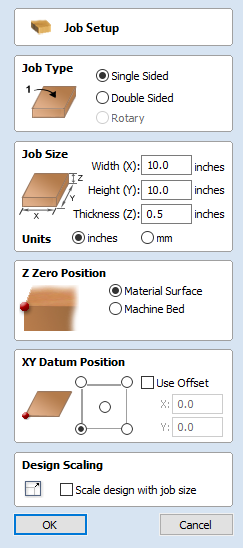

Job Setup - Single Sided

The Job Setup form is displayed whenever a new job is being created, or when the size and position of an existing job is edited.

Job Type

Single Sided job type should be used when design only requires the material to be cut from one side. This is the simplest type of job to design and machine.

For more information about Double Sided job type see Job Setup - Double Sided.

Job Size

This section of the form defines the dimensions of the material block you will be using for your project in terms of width (along the X axis), height (along the Y axis) and thickness (along the Z axis).

It also allows you to select which units of measurement you prefer to design in - either inches (Imperial/English) or millimeters (Metric).

Z Zero Position

Indicates whether the tip of the tool is set off the surface of the material (as shown in the diagram) or off the bed / table of the machine for Z = 0.0.

XY Datum Position

This datum can be set at any corner, or the middle of the job. This represents the location, relative to your design, that will match the machine tool when it is positioned at X0, Y0. While this form is open, a red square is drawn in the 2d view to highlight the datum's position.

Use Offset

This option allows the datum position to be set to a value other than X0, Y0.

Design Scaling

When editing the Job Size parameters of an existing job, this option determines whether any drawings you have already created will be scaled proportionally to match the new job dimensions. If you wish to preserve the existing size of your drawings, even after the job size has changed, leave this option unchecked. With this option checked, your drawings will be re-sized to remain in the same proportion and relative position within your new material extents when you click .